What is a tangential blower?

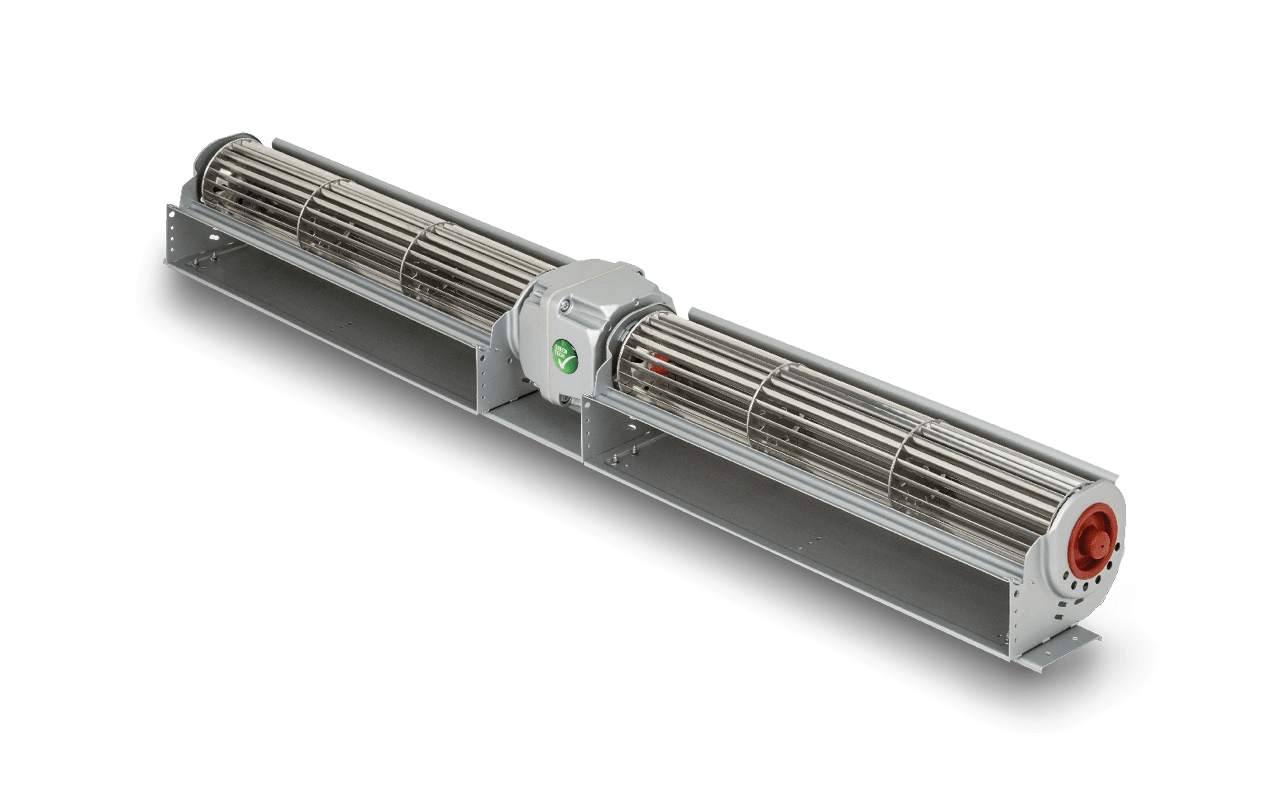

Tangential blowers consist of cylindrical impellers with blades arranged parallel to the axis of rotation. The air flows through the impeller twice in a centrifugal pattern: first from the outside to the inside and then from the inside to the outside. This double flow ensures wide, even air distribution and makes them ideal for applications with flat exposure.