Innovative ventilation solutions for the most demanding requirements

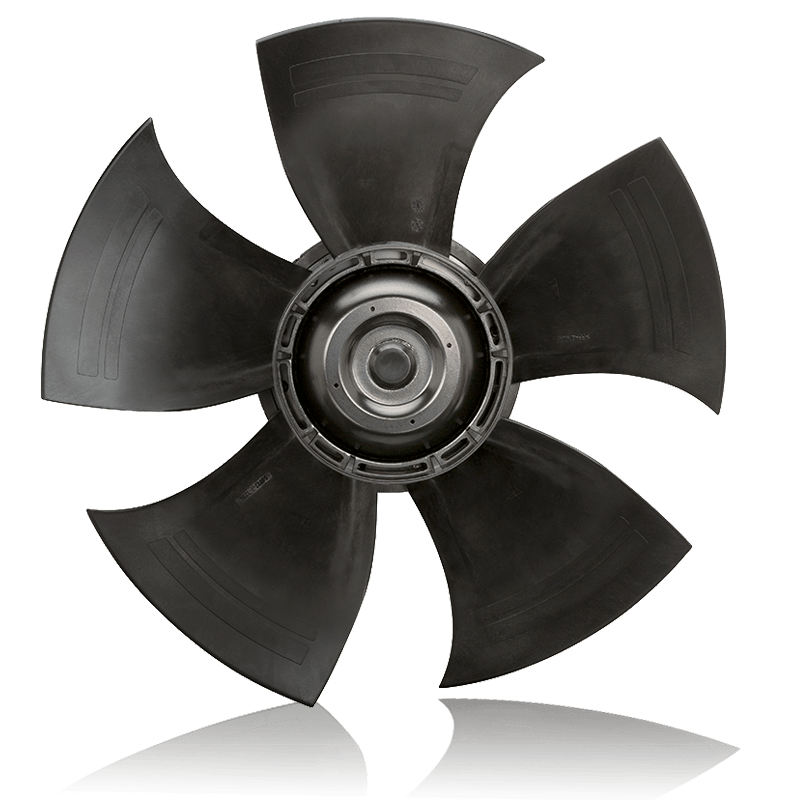

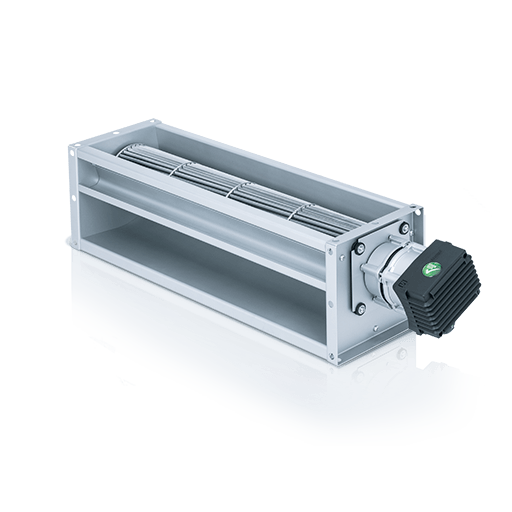

A fan consists of an impeller, a drive motor, and a housing for flow control to move air. An industrial fan is a high-performance fan that has been specially developed for demanding industrial applications. These industrial fans are designed to operate reliably even under high loads and to meet a wide range of requirements in areas such as ventilation technology, air conditioning, and mechanical engineering.

ebm‑papst offers a comprehensive range of industrial fans that feature state-of-the-art technology, exceptional energy efficiency, and high performance.