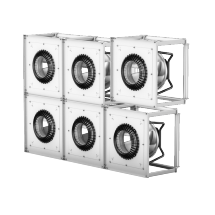

RadiPac:

One series, many applications

Energy-saving, quiet, compact, reliable: HVAC systems place high demands on the centrifugal fans used. RadiPac meets these demands with top marks! And it does so in almost all areas of ventilation and air conditioning technology – from standard applications to special applications.

To get the most out of every application, RadiPac is available in different versions, with numerous features and matching accessories – such as the innovative FlowGrid guide grille, which significantly reduces noise emissions without compromising efficiency.

Intelligent data usage is also playing an increasingly important role in ventilation and air conditioning technology. One intelligent feature that the latest generations of RadiPac EC centrifugal fans already have on board is automatic resonance detection. This allows critical speeds in the respective application to be detected and “suppressed.”