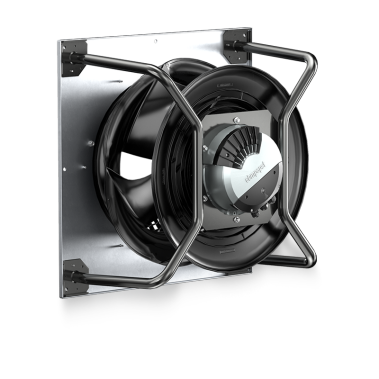

We don't just focus on the heat exchanger and its fans, but on the overall system. After all, our customers' needs are the key to us. For us, it goes without saying that a system has to operate reliably and efficiently. We of course also considered ease of maintenance and operation when developing our devices. Our highly qualified staff ensure that the latest technologies are always implemented. All control components are automatically configured and dimensioned to match the heat exchanger in our Güntner Product Calculator (GPC). This provides you with a ready-configured plug-and-play device. Our recipe for success: Forward-looking development, geared to the needs of our customers. Optimized production processes for outstanding quality. To achieve our primary goal: Maximum customer benefit.

Functional areas of Güntner Motor Management (GMM)

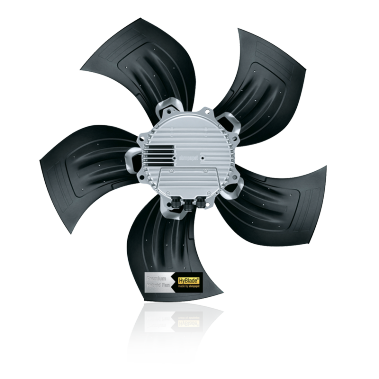

The GMM developed specially for Güntner heat exchangers is a tailored system that achieves the best possible efficiency in terms of heat dissipation, so enhancing the cost-effectiveness of the refrigerating plant. The application of sophisticated technology in the controller and in optimizing output ensures maximum service life of the heat exchanger and the fans. The GMM automatically configures fans and power components, enabling plug-and-play operation. All GMM systems use state-of-the-art bus technology. This serves as the basis for the GMM to handle the three main tasks of information, system and process management.

Information manager

Greater security and transparency for plant operation. As an information manager, the GMM provides communication interfaces to higher-level control systems and lower-level components such as variable frequency drives, EC fans, etc. Its display shows all key operational information, making it available to higher-level systems via a bus system or standard interface. This enables remote maintenance, and means operational indicators can be accessed at any time. This communication capability enhances security and transparency for plant operation.

System manager

Monitoring over the entire system lifecycle. The GMM monitors all key components of the heat exchanger. In the case of AC fans, for example, this includes their thermal contacts, the power electronics, and control cabinet components. Power components are configured automatically in the process. The GMM manages EC fans during commissioning, plant operation, and servicing. If a power component or an EC fan has to be replaced during servicing, all parameters are programmed automatically. This plug-and-play system automatically programs everything to match the respective design point of the heat exchanger, promptly displaying detailed information.

Process controller

Process control for energy-optimized operation. The GMM regulates the speed of the fans depending on the pressure or temperature, and controls processes, so creating an energy-optimized heat exchanger system. For pressure control, the refrigerant can be selected on the display. The condensation pressure and temperature are then also shown on the display. Other settings, such as the type of refrigerant or setpoint values, can also be made directly using the plain-text display.