DCV - Demand Controlled Ventilation

This term describes the demand-controlled operation of a ventilation system. The air exchange rate relates to the current room demand, not to the calculated full load. Air quality and temperature are used as control variables for the associated precision air flow controllers (VAV-Compact) from Belimo.

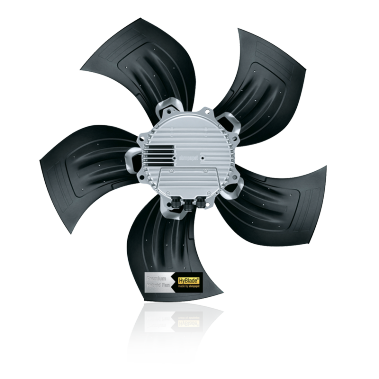

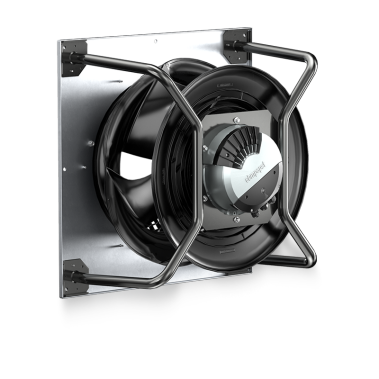

The fans in the air conditioning system run according to demand and energy-efficiently. To achieve this, the demand of the downstream air flow controllers is used directly to control the intelligent infinitely variable EC fans. Only the exact pressure necessary to transport the required partial air flow through the duct system is generated. DCV systems of this kind conform to energy efficiency class A, EN 15232 - Energy efficiency of buildings, and are a byword for highly energy-efficient building automation and technical building services management. Are you looking for ventilation systems offering high levels of comfort combined with low energy consumption? With a DCV system, that’s no longer wishful thinking!

Note:

Conventional admission pressure-controlled ventilation systems are operated in such a way that the admission pressure matches the full load volume continuously, even when running at partial load most of the time. The excess admission pressure generated at partial load is eliminated by the damper blades of the downstream VAV boxes. The consequences:

- Excessively high duct pressure with unnecessary pressure loss in the duct system and via the VAV boxes.

- Increased flow noise.

- Unnecessarily high energy consumption by the fans.