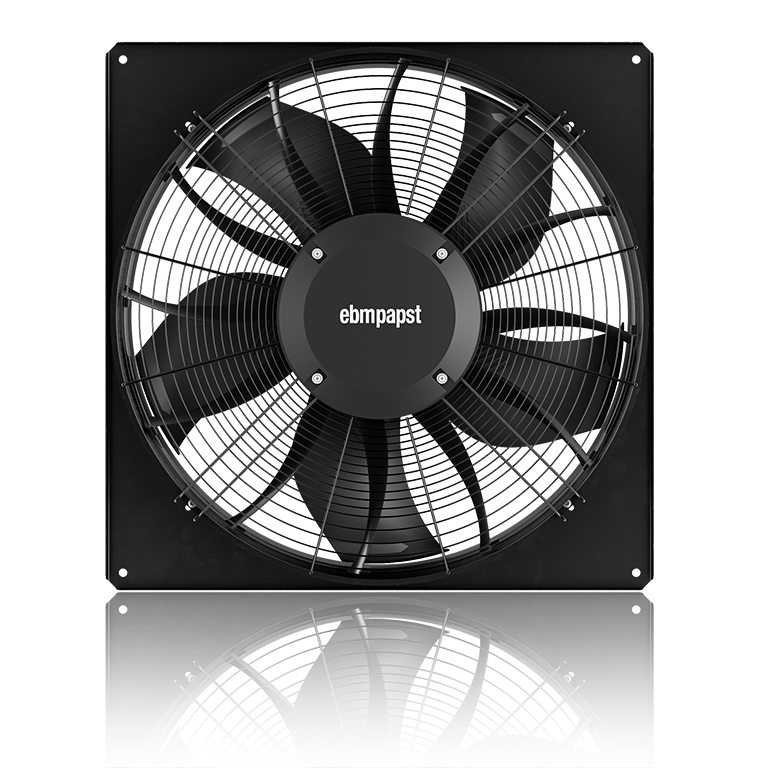

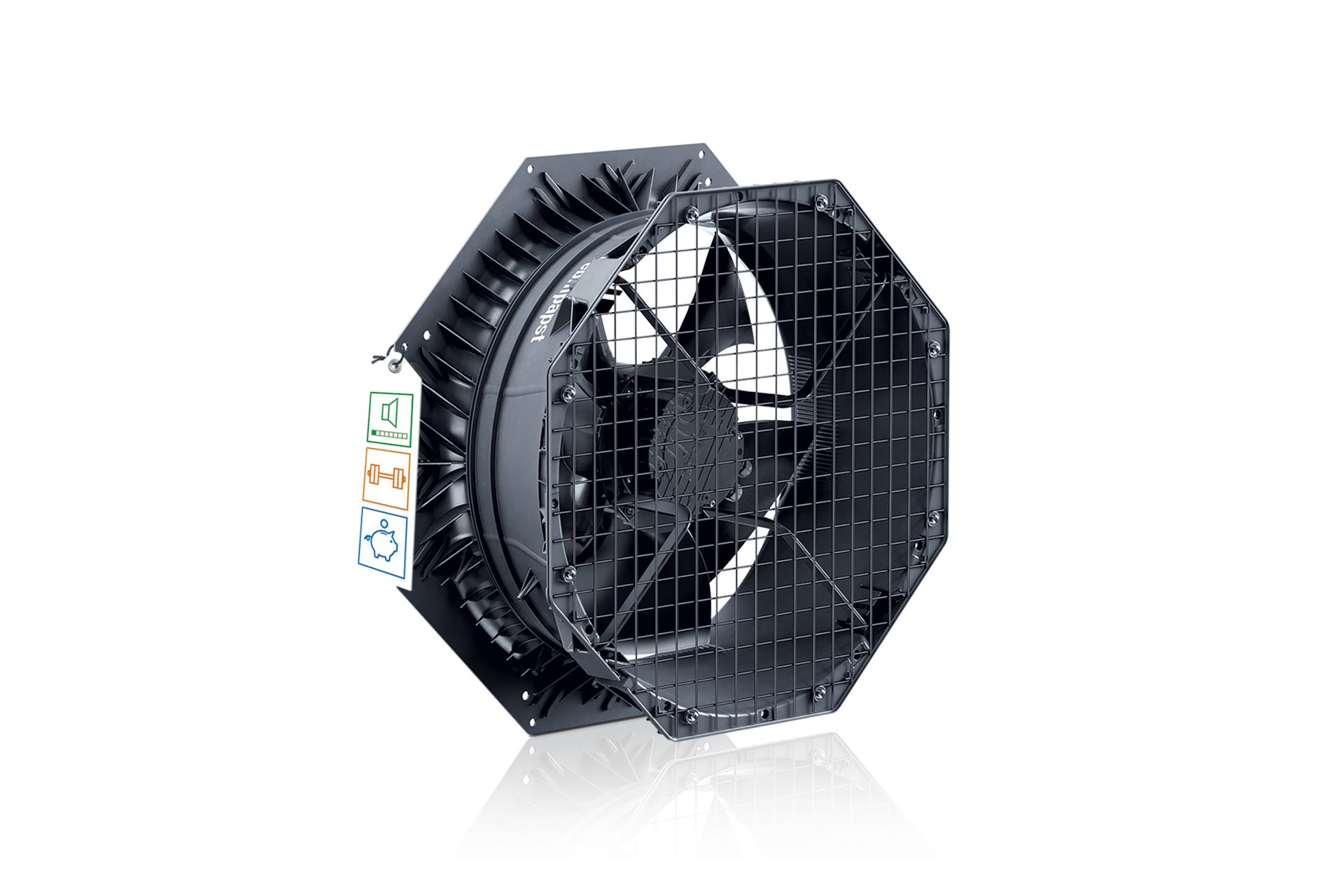

HyBlade® axial fans

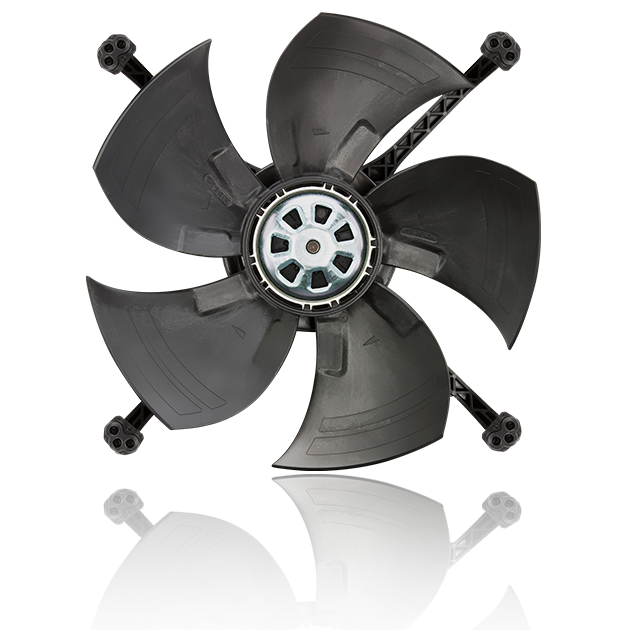

ebm-papst is adding new strengths to large axial fans with HyBlade®, an innovative hybrid structure for fan blades that is currently one-of-a-kind! The combination of an aluminum core and a glass-fiber-reinforced plastic covering sets an entirely new benchmark in terms of aerodynamic criteria. In particular, the aerodynamically optimized shape yields enormous advantages in terms of noise, whilst achieving even better efficiency than conventional blades.

But our development engineers also had optimized efficiency, enhanced corrosion protection, a lower weight, and ecological manufacturing with a favorable energy balance on their agenda. That’s why we are not satisfied with just making a few minor evolutionary modifications to what we already have. The next stage in development involves taking a huge leap forward. With a very impressive result: