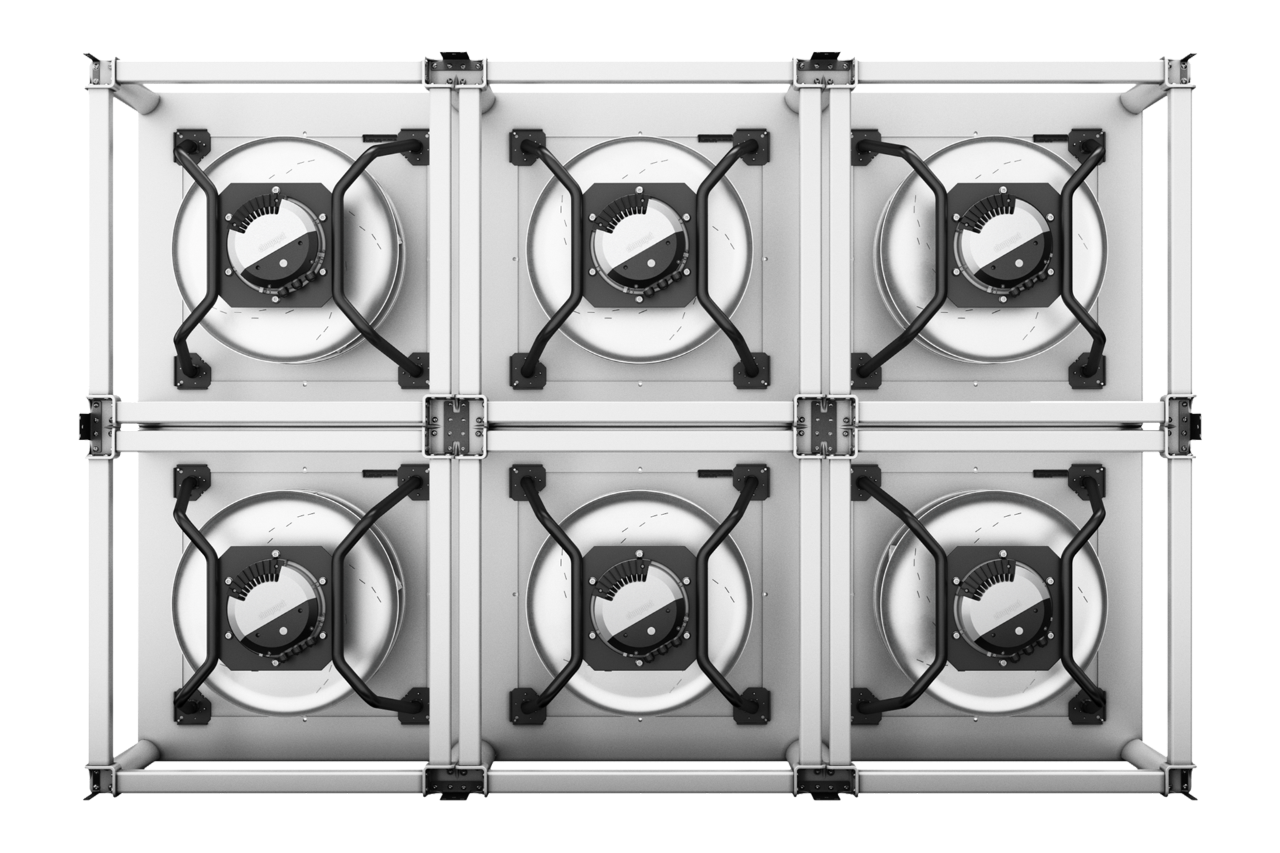

RadiPac stands for ...

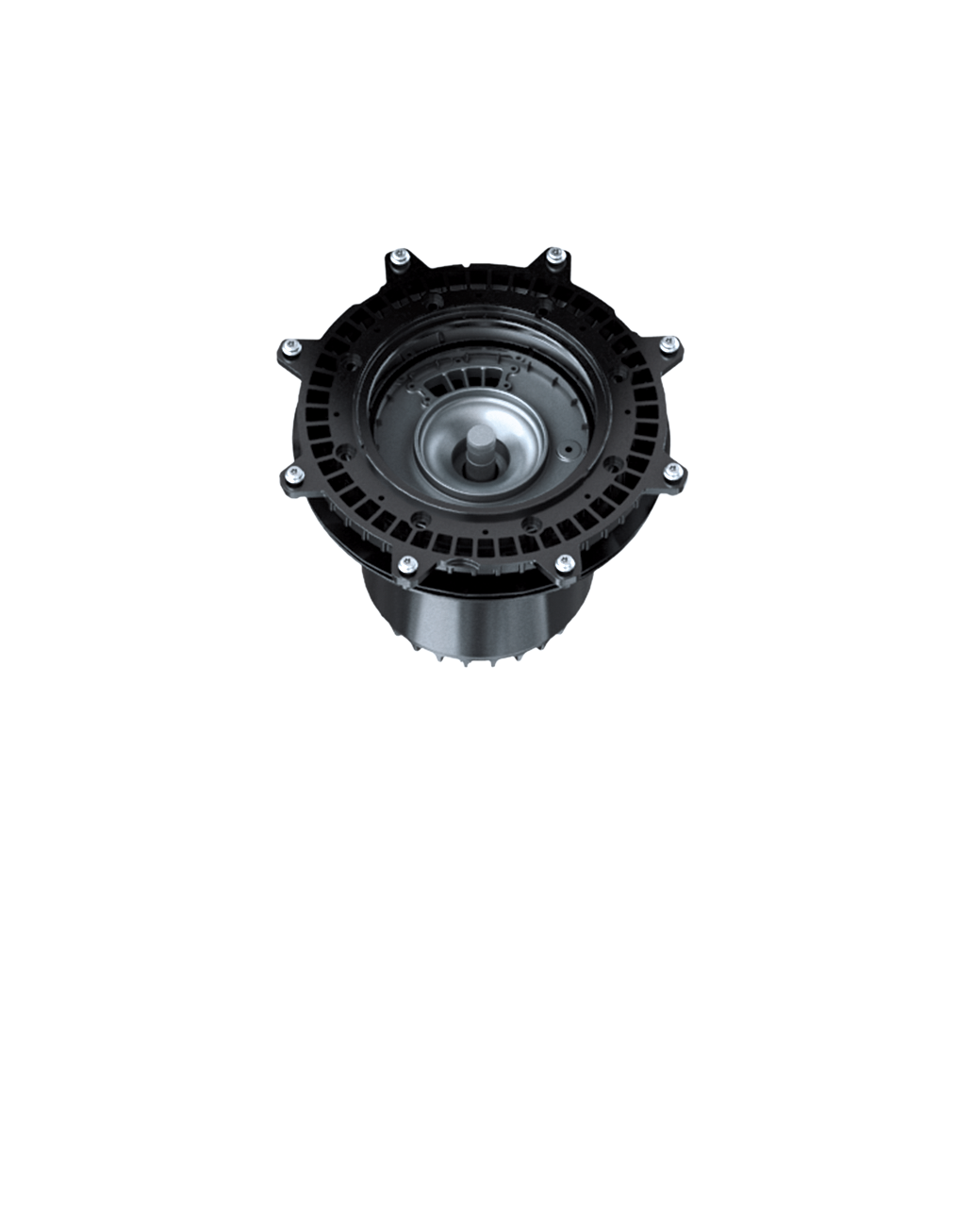

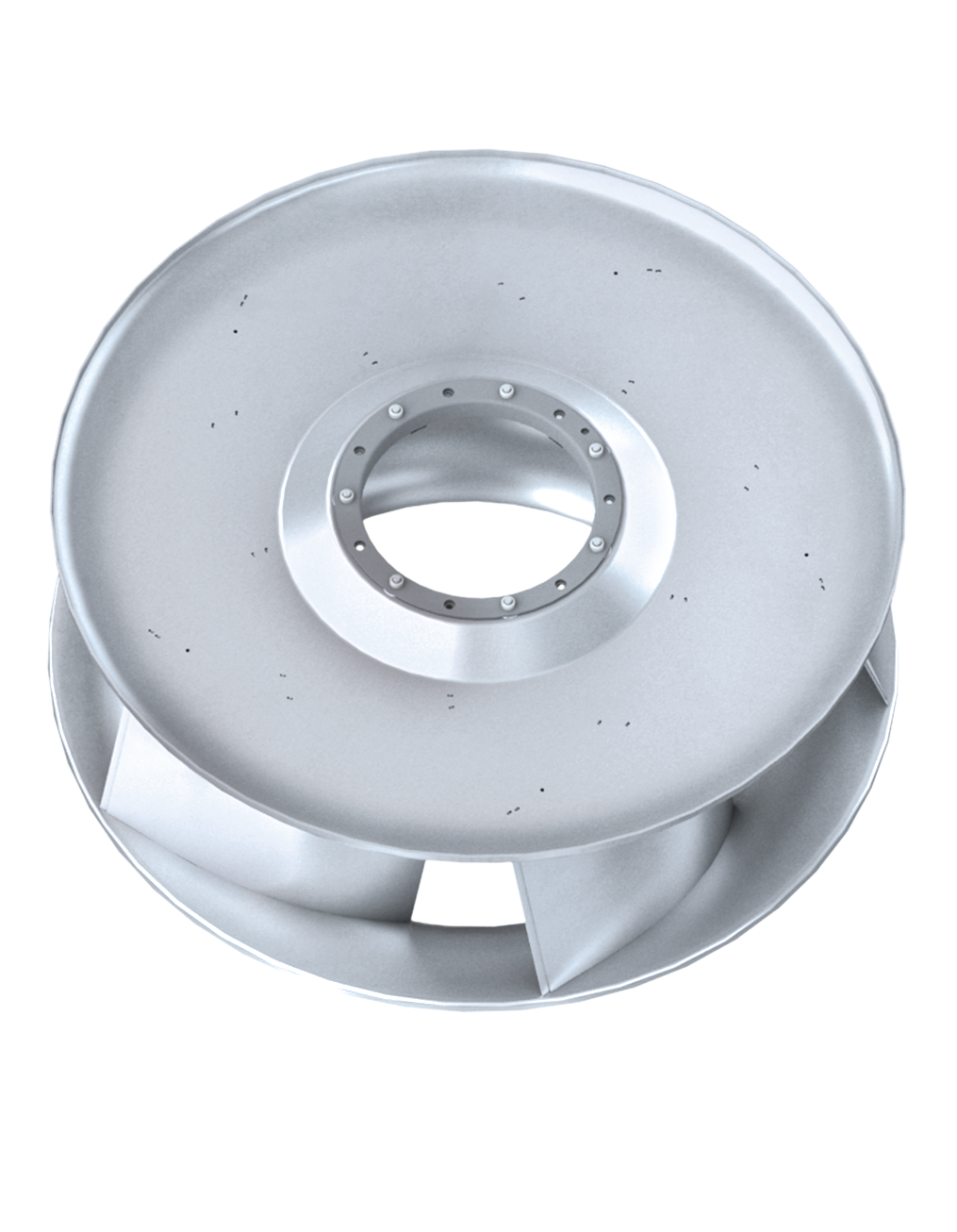

True performance figures, because the performance data is always measured for the entire fan consisting of high-performance impeller, GreenTech EC motor and control electronics.

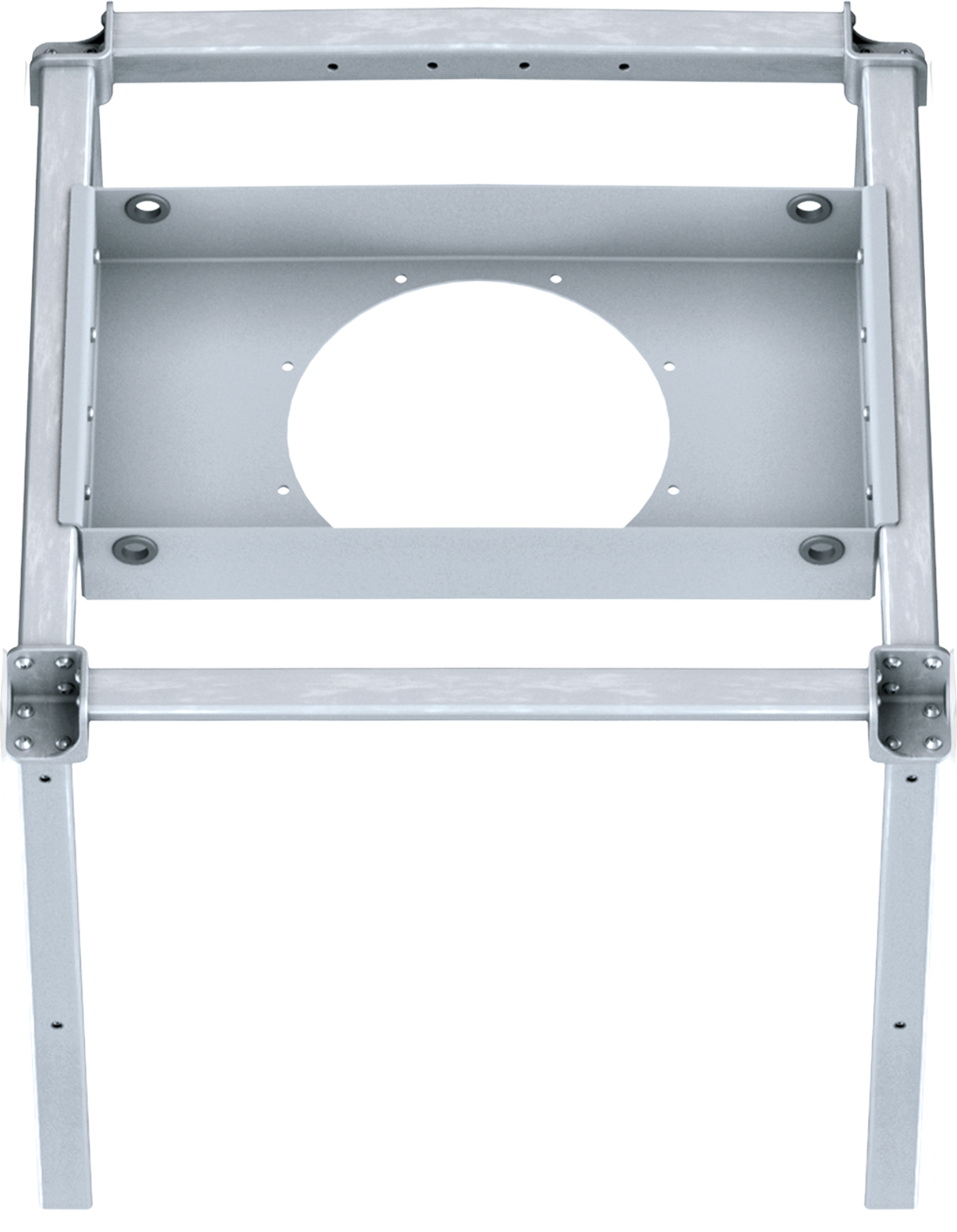

Effective logistics, because a single RadiPac part number covers all the components required for your ventilation application – one-stop shopping.

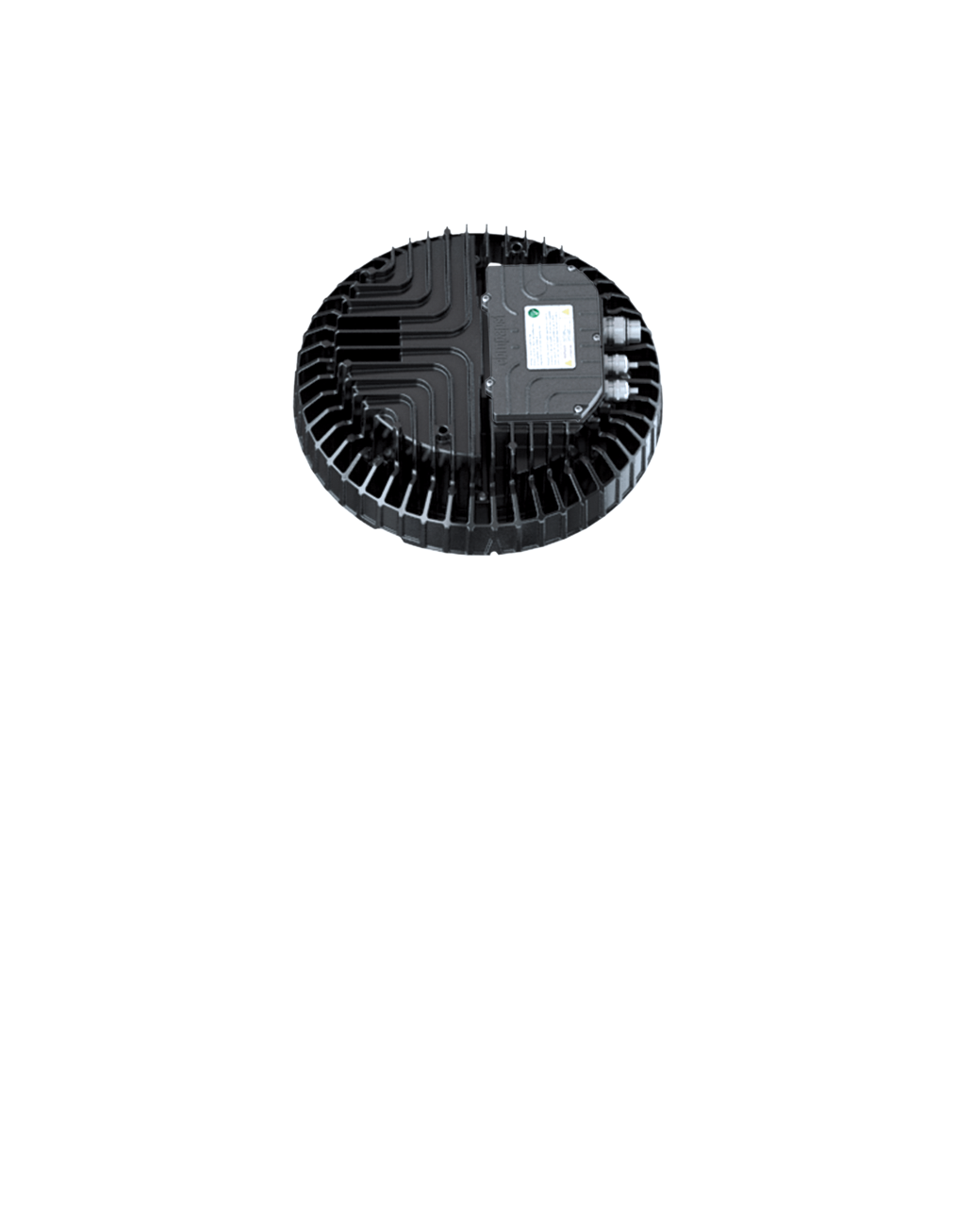

Easy commissioning, because all the functions required for operation are already incorporated and coordinated.